AMMONIA SCRUBBERS

100000 INR/Unit

Product Details:

- Instruments Type Online Gas Detector / Controller (Optional)

- Measurement Concentration of Ammonia (NH3), Flow Rate

- Automation Grade Semi-Automatic / Automatic

- Temperature Ambient to 60C

- Orientation Vertical / Horizontal

- Efficiency Up to 99% removal efficiency

- Air Flow Adjustable, as per system design

- Click to View more

X

AMMONIA SCRUBBERS Price And Quantity

- 100000 INR/Unit

- 10 Unit

AMMONIA SCRUBBERS Product Specifications

- Continuous

- Vertical / Horizontal

- Customized as per clients requirement

- 500 m/hr to 50000 m/hr

- Ambient to 60C

- Below 75 dB(A)

- Semi-Automatic / Automatic

- Ammonia Scrubber System

- Varies as per design

- Concentration of Ammonia (NH3), Flow Rate

- Online Gas Detector / Controller (Optional)

- 6 mm to 10 mm

- Industrial exhaust gas treatment, chemical plants, ammonia emission control, fertilizer industries

- Corrosion Resistant, Smooth Finish

- Electric

- Analog / Digital (Optional)

- Packed Bed / Wet Scrubber

- Adjustable, as per system design

- Electrochemical / Semiconductor (Optional)

- Water Cooled / Air Cooled

- Up to 99% removal efficiency

- 380 V / 415 V

- FRP / PP / PVC / Mild Steel

AMMONIA SCRUBBERS Trade Information

- 10 Unit Per Month

- 10 Days

Product Description

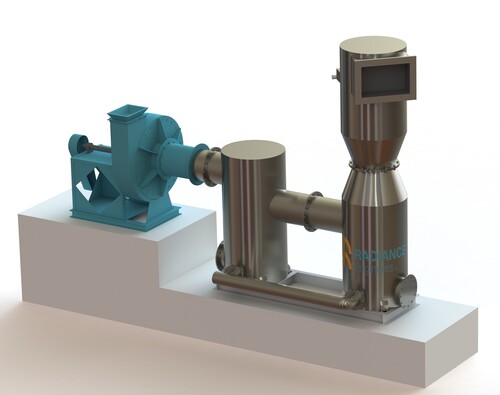

Ammonia Scrubbers remove pollutants via a chemical reaction as opposed to Particulate Scrubbers which inject liquid into the gas stream. Ammonia Scrubbers have proven to be very effective at removing the ammonia from exhaust streams using this method.Integrated pH Monitoring for Enhanced Control

The ammonia scrubber systems come equipped with pH monitoring, ensuring precise control of the scrubbing liquid. This integration helps maintain optimal chemical conditions for effective ammonia absorption and minimizes operational risks. Real-time display options further simplify monitoring and enhance regulatory compliance for industrial applications.

High-Efficiency Performance with Advanced Features

Our scrubbers deliver up to 99% removal efficiency, supported by centrifugal blowers, specialized packing materials like PP Pall Rings or ceramic saddles, and built-in mist eliminators. The systems accommodate gas inlet temperatures up to 60C and feature continuous processing for uninterrupted ammonia control in demanding industrial environments.

Customizable Design for Various Applications

Designed for versatility, the scrubber systems offer both vertical and horizontal orientations with stack or customized discharge outlets. Clients can select materials ranging from FRP, PP, PVC, or mild steel, and cooling methods tailored to specific needs. Dimensions, capacity, and air flow are fully customizable for diverse usage such as chemical plants, fertilizer industries, and industrial exhaust treatment.

FAQ's of AMMONIA SCRUBBERS:

Q: How does the integrated pH monitoring benefit ammonia scrubber operation?

A: Integrated pH control enables accurate management of the scrubbing liquid's chemical balance, which is crucial for optimal ammonia absorption. This leads to enhanced efficiency, reduced chemical consumption, and helps prevent corrosion, thereby supporting safer and more reliable scrubber operation.Q: What is the process used by these ammonia scrubbers to remove ammonia from exhaust gases?

A: The systems use either packed bed or wet scrubbing techniques, where contaminated gas passes through a bed packed with PP Pall Rings or ceramic saddles. The scrubbing liquid reacts with ammonia, while mist eliminators capture fine droplets, resulting in high-efficiency ammonia removal.Q: When should routine maintenance be performed on the ammonia scrubbers?

A: Although the scrubbers are designed for low maintenance, regular inspection via accessible manholes and inspection ports is recommended to ensure uninterrupted operation. Schedules can be established based on operating hours, gas concentration levels, and manufacturer guidelines.Q: Where can ammonia scrubbers with pH monitoring be applied?

A: These systems are primarily used in industries where ammonia emissions are prevalent, such as chemical plants, fertilizer manufacturing facilities, and other industrial exhaust gas treatment locations. Their versatile design enables installation in both new and existing infrastructure.Q: What safety controls are available with the ammonia scrubber systems?

A: An optional emergency shutdown device is available to immediately halt system operation in case of a detected anomaly or hazardous condition. Additional instrument options include online gas detectors and controllers, ensuring compliance with safety standards and environmental regulations.Q: How do users benefit from the ammonia scrubber's low noise and corrosion-resistant construction?

A: The scrubbers operate at noise levels below 75 dB(A), which creates a safer and more comfortable working environment. The use of corrosion-resistant materials, such as FRP, PP, and PVC, ensures long-term durability and reduces costs related to replacement or repairs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email