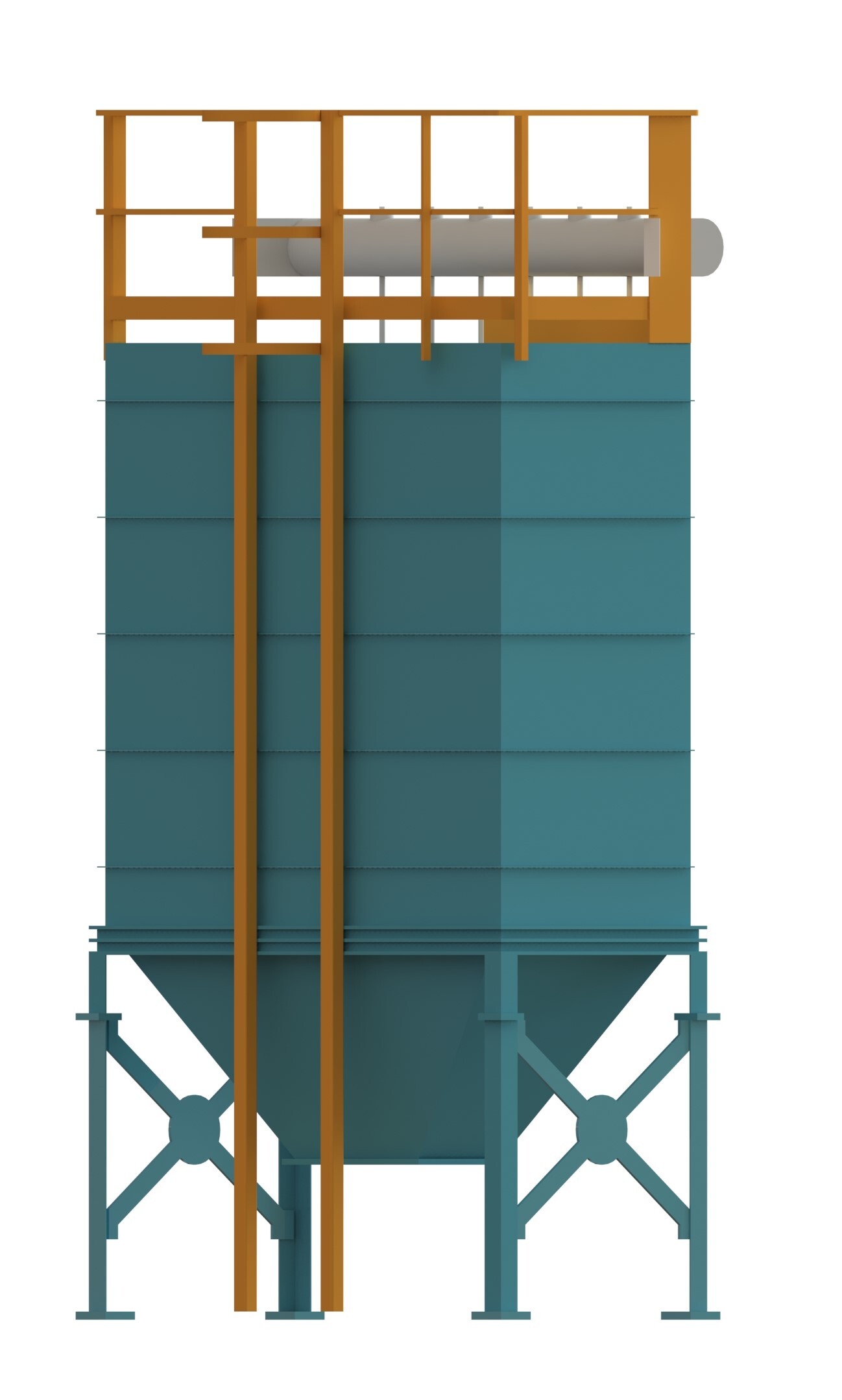

INDUSTRIAL BAG FILTER SYSTEMS

80000 INR/Unit

Product Details:

- Efficiency (%) 95% - 99.9%

- Capacity 5,000 CFM - 20,000 CFM Pcs/hr

- Diameter 200mm - 1000mm Millimeter (mm)

- Type Black Wire Cloth

- Material Stainless Steel

- Working Temperature 50C to 200C Celsius (oC)

- Click to View more

X

INDUSTRIAL BAG FILTER SYSTEMS Price And Quantity

- 80000.00 - 100000.00 INR/Unit

- 80000 INR/Unit

- 10 Unit

INDUSTRIAL BAG FILTER SYSTEMS Product Specifications

- Stainless Steel

- 95% - 99.9%

- Black Wire Cloth

- 200mm - 1000mm Millimeter (mm)

- 50C to 200C Celsius (oC)

- 5,000 CFM - 20,000 CFM Pcs/hr

INDUSTRIAL BAG FILTER SYSTEMS Trade Information

- HAZIRA PORT

- 5 Unit Per Month

- 10 Days

- All India

Product Description

We are engaged in manufacturing a wide array ofAir Pollution Control Bag Filterswhich is used to control increasing air pollution. These equipmentsfilter the contaminated air and provide fresh air. The assortment of these equipmentss widely demanded in industries such as Cement, Steel, Power, Sugar and Distilleries, Paper and Pulp and Chemical. These Bag Filters ensures recovery of particulate substance from exhaust gas is essential for two aspects of the industry i.e. to avoid the problem of pollution and recovery of finished products raising the plant yield.Engineered for High Efficiency

Achieving up to 99.9% filtration efficiency, our industrial bag filter systems offer reliable air purification for various industrial applications. The use of robust stainless steel ensures structural integrity at high temperatures, while black wire cloth enhances particle retention, supporting both employee safety and environmental compliance.

Flexible Capacity and Temperature Range

Suitable for operations requiring air capacities between 5,000 and 20,000 CFM per hour, our systems are equipped to manage substantial airflows while maintaining consistent performance. They operate effectively in temperature environments from 50C up to 200C, making them versatile for industries like cement, metal processing, and chemical manufacturing.

Made in India, Exported Worldwide

As a trusted exporter and manufacturer in India, we supply industrial bag filter systems globally. Each product undergoes rigorous quality control, ensuring adherence to international standards and rigorous operational demands. Our expertise allows us to deliver tailored solutions for diverse industrial requirements.

FAQs of INDUSTRIAL BAG FILTER SYSTEMS:

Q: How does the industrial bag filter system achieve high filtration efficiency?

A: The system uses a combination of stainless steel construction and black wire cloth to effectively trap dust and fine particulates. Its design enables filtration rates between 95% and 99.9%, ensuring clean, filtered air even in challenging industrial environments.Q: What materials are used in manufacturing these bag filter systems?

A: The primary material is high-grade stainless steel, chosen for its resistance to corrosion and high temperatures. The filtration medium is black wire cloth, which supports optimal particle capture and longevity of the filter unit.Q: When should an industrial facility consider installing a bag filter system of this capacity?

A: Facilities with significant dust or particulate emissions, especially those operating processes between 5,000 and 20,000 CFM airflows and temperatures from 50C to 200C, should consider this system for regulatory compliance, workplace safety, and equipment protection.Q: Where are these industrial bag filter systems typically installed?

A: Common installation sites include heavy manufacturing plants, cement factories, steel foundries, and chemical production unitsanywhere robust air filtration is needed to maintain air quality and protect machinery.Q: What is the process of installing an industrial bag filter system?

A: Our installation process involves an assessment of site requirements, followed by customization of system diameter (200mm1000mm) and capacity. Professional mounting, integration with ducting, and performance testing ensure the system operates at optimal efficiency.Q: How is the filter system maintained to ensure consistent efficiency?

A: Regular inspection and cleaning of the wire cloth and filter bags are recommended. Maintenance schedules depend on dust load, but prompt replacement or cleaning extends the service life and sustains high filtration rates.Q: What are the key benefits of using a stainless steel bag filter system in industrial applications?

A: Stainless steel provides durability, resistance to harsh chemicals, and greater longevity. Combined with high particulate capture efficiency, these systems support regulatory compliance, reduce environmental impact, and lower maintenance needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email